Historian Michel Foucault tells how, in the 17th Century - what we would call the first era of the modern novel - readers perceived novels as a form of distraction. Through a novel, the reader could “become” another person, effectively leaving their own body behind and experiencing a new reality. Immersing oneself in the adventure on the printed page was to live a kind of apparent reality made only from figments of the author’s and reader’s imagination. Cervantes was one of the first to hint at this possibility through his ingenious gentleman Don Quixote, fueling the craze for a certain type of literature, a mix of chivalric legends and real world.

If, back then, the vicarious effects of the novel also begot its detractors, can you imagine what 17th C. people would make of the amazing power of today’s extended reality? To watch us singing in a virtual concert? Learning how to fly a plane with an Augmented Reality simulator?

Technology that dissolves the boundaries of reality is already here. Thanks to Augmented, Virtual and Mixed Reality, we can offer innovative solutions that provide us with working, learning and leisure alternatives. Even the most hardened 17th Century doubter might, on witnessing this, come to abandon their reluctance and embrace the potential of perfectly combining physical and created reality.

ACCIONA has invested years exploring the potential of Extended Reality (the term used to encompass Augmented, Virtual and Mixed Reality) in professional environments: virtual tours, telematic meetings, visualization of referenced objects for construction projects, etc.

You’ll discover articles on these technologies elsewhere in this website, such as the amazing Arch of San Pedro de las Dueñas 3D printing project carried out by ACCIONA for the National Archaeological Museum (MAN) in Madrid.

The project also entailed scanning and digitizing other valuable historical artefacts at the museum, enabling the creation of a digital twin of each of them, exact replicas of elements existing in the real world using a technology that allows us to carry out all kinds of simulations to optimize processes, carry out maintenance tasks, or even, in the case of the Dueñas Arch, “print reality”.

Our purpose here, though, is to show you the great use we can make of this technology in Industry 4.0 and, specifically, water management. Facilities such as ACCIONA’s Drinking Water Treatment Plants (DWTPs) already count on the use of immersive technologies in their operations, solutions which facilitate maintenance tasks and safely and efficiently train staff in the complex management of plant processes. Let’s go a bit deeper into what these projects involve.

Immersive technology operating in the Gartxeta DWTP, managed by ACCIONA, involved the creation of a digital twin of the whole plant and then integrating it into an Augmented Reality project.

On the one hand, the creation of the digital twin makes it possible to visit the entire plant in an immersive way with Virtual Reality glasses on a real scale and access information on all the plant's assets.

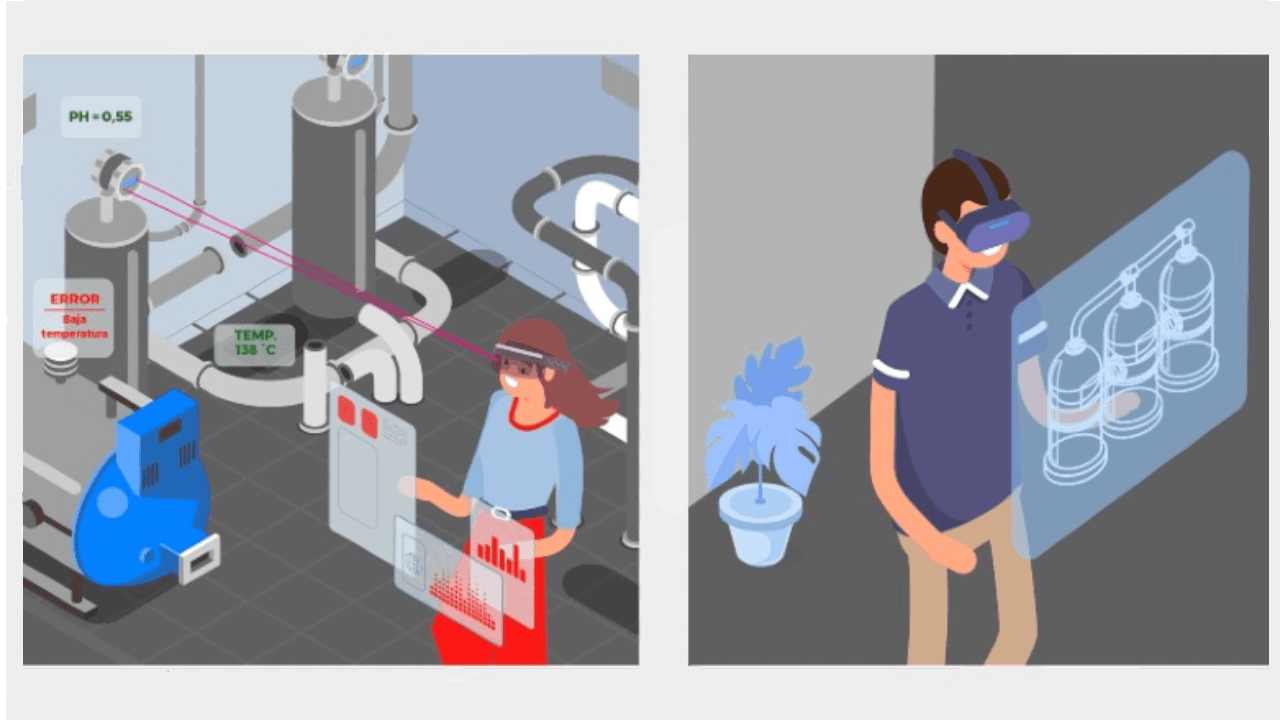

On the other hand, with the help of AR glasses or a smartphone, operators can access the content of all manageable assets: plant, service manuals, 360º videos, etc., i.e. enabling them to visualize a real element at a certain point in the plant, superimpose virtual information and even interact with it.

Suppose we have to do preventive maintenance in the water treatment plant. The person charged with doing so will be able to use AR glasses for this task. These glasses are capable of recognizing each element and showing a 3D virtual image that verifies the inspection step by step. The glasses can also be used to extract information from the different control systems to visualize it in real time and even could be used to operate the plant remotely.

The technology at Gartxeta also allows for remote assisted maintenance. Using the above example, if, during the inspection of the filter, the worker has a doubt, they can call on support from a colleague who can connect from anywhere else in the facility and, thanks to the camera in the headset, see the physical plant at the same time as superimposed virtual elements, as if she or he was there and physically helping with the task.

But what is really special about this technology? For Augmented Reality projects, we need to identify the different elements of the real world precisely. One of the best ways to do this is by superimposing a BIM model over the real plant, but this is only viable if we already have one. The BIM Cube methodology exclusive to ACCIONA performs the modeling from simple geometric forms instead of perfectly defined 3D ones.

BIM Cube methodology exclusive to ACCIONA is employed in such projects, creating the 3D model from simple geometric forms rather than using perfect texturization. These geometric forms “package” elements of the plant so that they can be recognized by the glasses and display the virtual information stored about them.

What are the advantages? Essentially, BIM Cube modeling is more economic and allows tasks to be completed much quicker than BIM modeling alone, thus optimizing the process and the cost of the task.

Maintenance at a DWTP involves tasks demanding great responsibility and rigorous knowledge of processes. Virtual Reality can be a great ally in training operators for these tasks.

This is why ACCIONA has developed a VR Training “experience” for Las Cruces DWTP, to prepare workers in chlorine procedures. The plant was scanned with high-precision devices, modeled in 3D, and texturized to make an exact virtual copy of the facility.

Using this technology, plant staff, especially new arrivals, can practise step by step virtually how, for example, we refill a chlorine container and repeat the experience as often as necessary until they have internalized the procedure. The training is similar to that they would undertake on the physical plant, but avoids the risk involved with managing substances such as chlorine.

It’s a routine procedure, but in no way trivial or intuitive. Virtual Reality contributes advantages that even reality cannot confer:

- VR training is estimated to be up to 80% more efficient than conventional training

- Operators can practise tasks as often as they like and return to a previous step when necessary

- They can safely and efficiently learn highly complex tasks involving hazards such as fire.

Sources: Imnovation Hub, Jot Down