On the ground of a plaza more than two hundred metres above sea level, an astronomical clock marks a moment in a 26,000-year cycle. It represents what is known as the precession of the equinoxes—the gradual tilt of Earth’s axis that slowly alters our view of the night sky. Translated into our era, the year is 1935. And the moment it marks, engraved into the structure itself, is the inauguration of the Hoover Dam in the United States. It was a project that pushed the boundaries of engineering and became the largest infrastructure of its kind in the 20th century.

The Hoover Dam was a monumental effort that brought water and electricity to the arid regions of Arizona and Nevada and it restored hope to a United States still grappling with the Great Depression. However, alongside its art deco splendor is an inscription that reads: “They died to make the desert bloom.” This phrase is a reminder of the toll of the project—not only in terms of economic challenges and construction difficulties but also in the loss of over a hundred human lives.

Nearly a century later, ACCIONA and their partners were tasked with building another dam in the neighboring country to the north. The mission was to construct under extreme weather conditions, ensuring sustainability and safeguarding every human life. This project will carry forward the legacy of iconic projects like the Hoover Dam, but with innovation at the heart of the construction approach.

The result is Site C, a massive dam that will deliver clean energy to nearly half a million British Columbian homes. It stands as one of ACCIONA's largest global infrastructure achievements and, after almost a decade of work, is now a reality. This article explores the process of creating a massive dam under extreme conditions, with temperatures plunging to -31°C, and displacing more than sixteen million cubic meters of earth—enough to fill six soccer stadiums.

How many energy infrastructure projects can generate renewable energy for a century while being built to withstand an earthquake that occurs once every 10,000 years? That was the ambitious mandate given to Site C by the province of British Columbia, requiring an innovative design from Peace River Hydro Partners (PRHP), a joint venture between ACCIONA Infrastructure Canada and Samsung Renewable Energy Inc. who were responsible for the main civil works contracts for the projects.

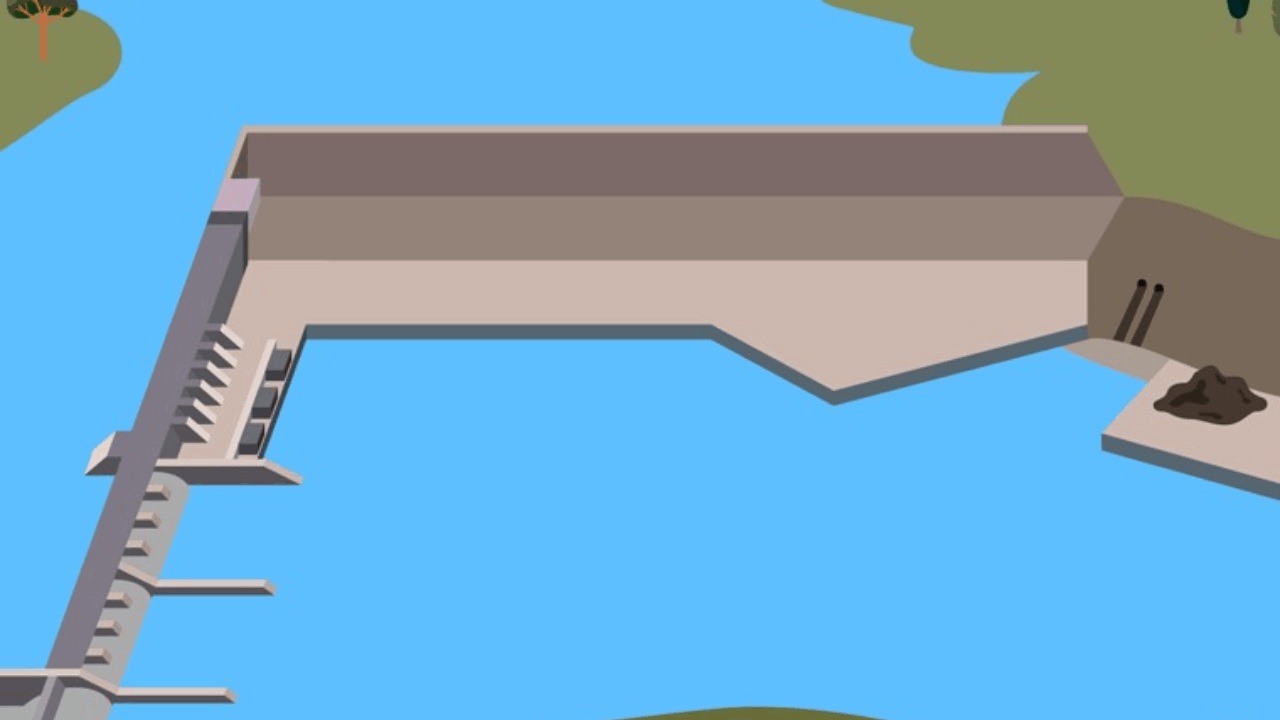

Situated along the Peace River, Site C is the third dam along this waterway in northern British Columbia. When you see the project, two features will immediately capture your attention. First, its sheer size—spanning nearly two kilometers across its two branches. Second, is its L-shaped configuration, combining an earthen embankment that dams the river head-on and a perpendicular section of roller compacted concrete and reinforced concrete.

These design elements are central to its mission: to ensure a robust infrastructure that will serve as one of British Columbia's energy cornerstones for the next century.

A photograph captures a night scene—a lone excavator at work beneath the ethereal green glow of the aurora borealis. This image shows two realities: construction at Site C never stopped, operating around the clock, year-round, and that it was carried out in a northern climate, often in freezing temperatures.

To tackle these challenges, the winter months were dedicated to planning, tunnel excavation, drilling, and grouting (injecting concrete to fortify the tunnels). As temperatures rose in spring, construction of the concrete dam accelerated. At the peak of construction in 2023, there were more than 6,000 workers on the project.

Before construction could begin on the dam, the Peace River’s course had to be temporarily diverted. This involved excavating two tunnels, each 800 meters long and 11 meters in diameter, which were operational from 2020 to 2024.

The next stage involved creating a massive earthen dam that stands about 60 metres tall, the height of a 20-storey building, stretches more than one kilometre across the Peace River, is about 500 metres wide at its base, and requires 16 million cubic meters of material. Most of this was sourced at the construction site, with the remainder transported via a five-kilometer conveyor belt.

The concrete dam that seals the reservoir in its L-shaped design required the equivalent of 280 Olympic-sized swimming pools of concrete and enough steel to build four Eiffel Towers.

While hydroelectric power is inherently renewable, the construction process must also adhere to sustainability principles. This involves two key aspects: implementing measures to minimize impacts on local wildlife and employing construction techniques and materials that reduce the carbon footprint.

Over the last decade, innovative strategies have been developed to mitigate the impact of hydroelectric power on aquatic ecosystems. For Site C, a temporary fishway was constructed to allow passage for fish ascending the Peace River during construction.

Near the end of construction, a permanent fishway was completed, enabling species like bull trout to be transported safely upstream of the dam. Additionally, BC Hydro, the dam’s owner and operator, restored various shallow-water habitats and reestablished streamside vegetation to support aquatic life.

On the construction front, reducing the carbon footprint was a top priority. One significant measure was the use of a nearly five-kilometer conveyor belt to transport glacial till, which formed the core of the earthfill dam. By replacing traditional trucks and utilizing renewable electric power, this strategy cut emissions by more than 1,500 tons.

At the Hoover Dam Museum, the recreations of the work environment reveal a striking detail, the lack of safety equipment for the workers who built it. Nearly a century later, the standards have improved dramatically. For Site C, ACCIONA implemented cutting-edge safety measures to mitigate risks in an environment characterized by extreme weather and heavy operations.

Dam construction involves moving massive quantities of earth and concrete, alongside the operation of heavy machinery. To enhance situational awareness, ACCIONA deployed a system called SCAN~LINK in addition to conventional safety measures.

This innovative system incorporated RFID tags on workers’ helmets and receivers on excavators and trucks, triggering audible alerts whenever an operator came within five meters of the machinery. Thanks to these advanced measures, no lives were lost during the project, which entered the testing phase at the end of 2024.

Scheduled to come into full operation by fall 2025, Site C, unlike its cousin the Hoover Dam to the south, does not feature an astronomical marker to commemorate its operational debut for future generations. In this age of digital impermanence, even this article recounting its story could fade into obscurity within a few short years. Yet, we remain confident that a century from now, the great-grandchildren of those who witnessed its construction will continue to benefit from the clean energy it provides year after year.