-

Today, Cebu city home to an incredible engineering work which is once more putting the Philippines on the map, and the route to progress and improved communications. That is, the Cebu bridge built by ACCIONA.

-

The Philippines is an archipelago of over 7,000 islands in the western Pacific Ocean. Its seas, which switch between mild and peaceful and violently stormy, have seen some of the most important episodes in navigational history.

One of the legends speaks of the “tornaviaje”, or trans-Pacific return route, the crossing from the East Indies to America that resulted in many a shipwreck due to its terrifying gales and currents. It was first successfully made from the port of Cebu on 1 June 1565, arriving four months later in Acapulco.

People unfamiliar with ships logs and navigators’ diaries probably won’t fully appreciate the magnitude of the achievement. It was the first time sailors had completed the return voyage from the Philippines to the American continent, but it also represented much more than that. It has been suggested that this voyage marked the first step in globalization: connecting the Old World to the economy of the Ming Dynasty and, in turn, the Americas. For over 250 years, the regular Manila Galleon line was the world’s main trade route.

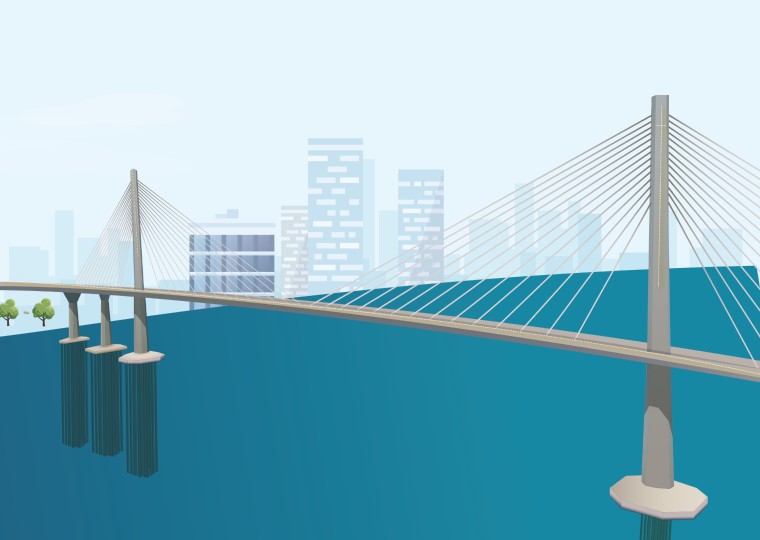

Today, five centuries later, this ancestral sea and its “bustling, coconut-smelling port” – as Gil de Biedma called it – is home to an incredible engineering work which is once more putting the Philippines on the map, and the route to progress and improved communications. That is, the Cebu bridge built by ACCIONA.

Below, we detail the numerous challenges engineers and operators have had to overcome in order to finalize this project, which is already an imposing symbol over the channel paves the way to the city.

-

-

The Philippine island of Cebu links via two bridges over the channel to the next island, Mactan, home of an international airport. But both these roads are continually gridlocked and drivers need to go through the city of Cebu to get to them, which is hugely inconvenient for the many thousands of people who need to cross from one island to the other every day.

Very soon, however, this problem will be past, thanks to a spectacular project constructed by ACCIONA: a 2.5-kilometer cable-stayed bridge with a 650-meter main structure allowing an 8.5-kilometer highway to connect the two islands.

-

Since the work began, the project awarded by Metro Pacific Tolls Corporation, has had to overcome logistical supply difficulties in a country spread across the middle of the Pacific. Even transporting the office computers turned out to be a coordination artform! Above all, though, the islands were also hit by two years of devastating pandemic, and the destruction and chaos left by Typhoon Rai (known in the Philippines as Odette) in 2021.

Despite these onslaughts, engineering at its greatest has won the battle against the elements. The hugely impressive, majestic, cable-stayed Cebu bridge is up, and soon to open, and can boast some colossal statistics: a main span of 390 meters between its two pillars and pylons, each of which has a height of 145 meters, foundation piles driving down 60 meters below the water, and a far from inconsiderable beam length of 52 meters.

It has been a titanic task, involving the most advanced engineering, to achieve all of this, from the foundations and pile caps, to the concreting and sea transport.

-

THE BEAM LAUNCHER MANUFACTURED BY ACCIONA, KEY TO THE PROJECT

The Cebu bridge project could also rely upon a key innovation to construct the accesses to the main bridge: a beam launcher designed and made by ACCIONA.

The manufacture of the launcher took seven months and over 25,000 hours of work, and consisted of an innovative rack-and-sprocket system that has become a benchmark in the sector. Its features give it better control while installing ramps and slopes. It is safer and more precise than conventional winch and cable systems.

This beam launcher, transported from Spain for the project, was able to raise beams weighing 110 tonnes, stretching 52 meters long, and with up to 7% gradients.

You can see it work in this video.

-

-

RESPITE FOR DRIVERS, AND THE CITY CAN BREATHE AGAIN

The most impressive and iconic part of ACCIONA’s project in Cebu is the cable-stayed bridge, 650 meters long, with a near-400-meter span between its towers. But this new infrastructure is also made up of several viaducts and a 5-km section of highway stretching over the channel’s embankments.

A total of 8.5 kilometers of expressway, two lanes in each direction, which provides an alternative to driving through the city and over around 50,000 cars will travel every day.

-

When it opens up to traffic, it’s expected that the bridge will free up the link roads to Mactan and economically boost the city of Cebu and Visayas region.

ACCIONA formed specialized teams of local laborers for the construction work, creating over 2,500 direct and indirect jobs. The project is attracting investment and has boosted the construction industry locally, meaning more employment for local communities and an extraordinary economic boost for the region.

-

ENGINEERING THAT CONNECTS

ACCIONA has built more than 600 bridges of all kinds and technical complexity: suspension bridges, hanging bridges, drawbridges, lifting bridges and so on. An amazing portfolio of design and innovation. Engineering that connects – and pulverizes the distance that needs to be travelled between two points.

Emblematic bridges such as Ting Kau in Hong Kong; Walterdale and Beauharnois in Canada; over the Clarence River in Harwood, Australia; the fjord at Roskilde, Denmark, and; Sant Boi for the high-speed railway between Madrid and Barcelona in Spain.

-

-

Quito prepares its first metro line

A project will serve more than 400,000 people each day and has 15 stations connecting neighbourhoods in the north and south of the city in just 34 minutes.

-

-

-

-